PP reagent bottle, HDPE reagent bottle, how to choose?

1.When using various centrifuges, all centrifuge tubes, centrifuge tube caps, baskets, adapters, etc. must be carefully balanced on the balance beforehand. The weight deviation during balancing shall not exceed the range specified in the centrifuge manual.

(1) Weight balance. Generally, precision balance requires a deviation of no more than 0.1g, and conventional applications generally require no more than 1g. The weight deviation must not exceed the range specified in the centrifuge manual.

(2)The density is balanced. The materials filled in the centrifuge tube must have similar densities, otherwise the load will be unevenly distributed.

(3) Try to avoid loading an odd number of centrifuge tubes in the rotor. When the rotor is only partially loaded, it should be evenly distributed so that the load is evenly distributed on the rotor body.

(4) When there are an odd number of centrifuge tubes, the balance tube must be filled with materials with similar densities.

2.When loading the solution, select a suitable centrifuge tube according to the nature and volume of the centrifuged solution and follow the specific operating instructions of the centrifuge.

The use of organic solvents in plastic tubes must meet the compatibility requirements with corresponding materials, and polypropylene (PP) centrifuge tubes (bottles) cannot be used in contact with gasoline, kerosene, etc. Polycarbonate (PC) centrifuge tubes (bottles) cannot be used in contact with gasoline, acetaldehyde, acetone, ethanol, isobutanol, cresol, etc. Polyethylene (PE) centrifuge tubes (bottles) cannot be used in contact with sulfuric acid (50%, 75%), benzene, gasoline, kerosene, etc.

3.When using a capless centrifuge tube, the liquid should not be filled too much, so as not to be thrown out during centrifugation, causing the rotor to be unbalanced, rusted or corroded.

4.When vacuuming is required to seal the centrifuge tube with a cap, it is generally required that the liquid must be filled to prevent the upper part of the plastic centrifuge tube from being deformed by vacuum during centrifugation.

5.The centrifuge tube is sterilized under high temperature and high pressure. The centrifuge tube should be separated from the cap. If the centrifuge tube is sterilized together after being screwed together, it will easily cause the deformation of the centrifuge tube and cause danger during the experiment.

Three Commonly Methods used for Centrifugation

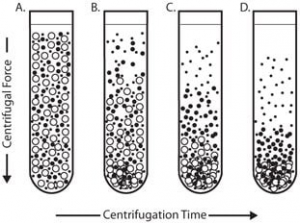

Differential Centrifugation

Differential centrifugation is often used for the extraction of crude products of biochemical samples. The difference in sedimentation coefficients of different suspended particles in the centrifugal force field is used. Under the same centrifugal conditions, different particles have different sedimentation speeds. By continuously increasing the relative centrifugal force, a non-uniform mixed liquid is formed Particles of various sizes and shapes are stratified and precipitated in the dispersion system.

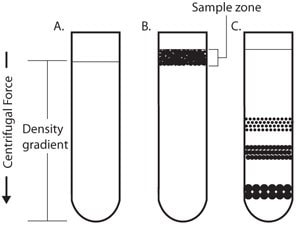

Rate Zonal Centrifugation

Velocity zonal centrifugation is an incomplete sedimentation separation. The sedimentation effect is greatly affected by the physical scale of the substance itself. It is generally used in the case where the size of the substance is different but the density is the same. Due to the different sedimentation velocities in the gradient liquid, the particles with different sedimentation velocities are in different density gradient layers after centrifugation, forming several separate sample zones to achieve the purpose of separation from each other.

When the velocity zone centrifugation method is used, the centrifugation time needs to be strictly controlled, not only to have enough time for various particles to form zones in the medium gradient liquid, but also to avoid any particles to be separated from forming a precipitation state.

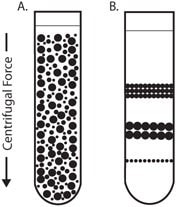

Isopycnic Zone Centrifugation

Isodensity zone centrifugation refers to the fact that when different particles in a liquid dispersion system have a difference in buoyant density, under the centrifugal force field, the particles either settle down or float up, and move along the gradient to the position where their densities are exactly equal, that is, equal density. Density points, centrifugation methods for forming zones.

The centrifugal effect of isopycnic zonal centrifugation depends on the buoyant density difference of the particles. The greater the density difference, the better the separation effect. It has nothing to do with the size and shape of the particles, but the latter two determine the rate, time, and zone to reach equilibrium, width.

SHANGHAI HXRT MD CO.,LTD. centrifuge tube is made of grade medical virgin polypropylene material,good sealing performance, max RCF is 15000xg,please contact us to get a instant quote:

Post time: Aug-17-2022